Pia-W-4088 Webbing

PIA-W-4088 Nylon Webbing is commonly used for parachute harnesses, waist straps, carrying handles and drag handles.

PIA-W-4088 Nylon Webbing is available in the following types: Type 3, Type 7, Type 8, Type 8B, Type 13, Type 17, and Type 26.

* IR Compliance - Available in all Military Colors

| Type | Class | Color | Width (inches) |

Thickness (inches) |

Tensile strength (lbs) |

|

|---|---|---|---|---|---|---|

| 13 | 1A | Sage green with black stripe | 1.75 | 0.08-0.12" | 7000 | DETAIL |

| 13 | 1A | Olive green with black stripe | 1.75 | 0.08-0.12" | 7000 | DETAIL |

| 13 | 1A | Coyote brown with black stripe | 1.75 | 0.08-0.12" | 7000 | DETAIL |

| 13 | 1A | Ranger with black stripe | 1.75 | 0.08-0.12" | 7000 | DETAIL |

| 7 | 1A | Naval blue with yellow stripe | 1.75 | 0.06-0.1" | 6000 | DETAIL |

| 7 | 1A | Tan with yellow stripe | 1.75 | 0.06-0.1" | 6000 | DETAIL |

| 7 | 1A | Coyote with yellow stripe | 1.75 | 0.06-0.1" | 6000 | DETAIL |

| 7 | 1A | Camo green with yellow stripe | 1.75 | 0.06-0.1" | 6000 | DETAIL |

| 7 | 1A | Black with yellow stripe | 1.75 | 0.06-0.1" | 6000 | DETAIL |

* For any other Mil-Spec or Commercial Elastic not listed above, please contact us

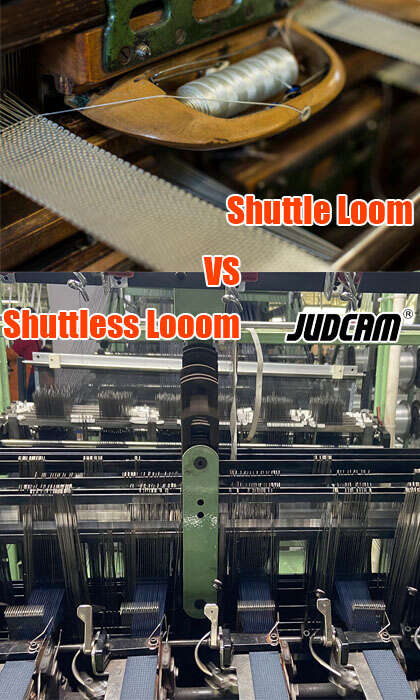

Comparison of shuttle and shuttleless looms

The shuttle loom is a weaving machine which uses the traditional shuttle (wooden shuttle or plastic shuttle) weft insertion. The shuttle is large in volume and heavy in weight, and is repeatedly projected by the traffic, the machine vibrates greatly, the noise is high, the speed is slow, the efficiency is low.

The weft-insertion method of shuttle-less loom is various, including Rapier, Jet (Jet, water spray), projectile, multi spindle mouth (multiphase) and knitting. Advantages of shuttle less looms:High labour and machine productivity due to high speed and wider width of looms.

Webbing produced on shuttle and shuttleless looms visual differences may be subtle。

Our PIA-W-4088 meet the demands of the parachute industry Class 1a (critical use, shuttleless / needle loom), and Class 2 (non-critical use, shuttleless / needle loom) material.

The shuttle loom is a weaving machine which uses the traditional shuttle (wooden shuttle or plastic shuttle) weft insertion. The shuttle is large in volume and heavy in weight, and is repeatedly projected by the traffic, the machine vibrates greatly, the noise is high, the speed is slow, the efficiency is low.

The weft-insertion method of shuttle-less loom is various, including Rapier, Jet (Jet, water spray), projectile, multi spindle mouth (multiphase) and knitting. Advantages of shuttle less looms:High labour and machine productivity due to high speed and wider width of looms.

Webbing produced on shuttle and shuttleless looms visual differences may be subtle。

Our PIA-W-4088 meet the demands of the parachute industry Class 1a (critical use, shuttleless / needle loom), and Class 2 (non-critical use, shuttleless / needle loom) material.

Resin Impregnated

Class R= Resin impregnated

Class L = Latex impregnated

Treatment that can apply to all types of MIL-W-4088

MIL-W-4088 nylon webbing is very flat and smooth and slightly stiff due to resin impregnation for abrasion resistance via MIL-W-27265. Perfect for edge binding and high wear areas.

Class R= Resin impregnated

Class L = Latex impregnated

Treatment that can apply to all types of MIL-W-4088

MIL-W-4088 nylon webbing is very flat and smooth and slightly stiff due to resin impregnation for abrasion resistance via MIL-W-27265. Perfect for edge binding and high wear areas.

Breaking Strength Test

We have been providing services to the military.

producing military webbing that meets strict international and local standards.

Rigorous testing in our in-house laboratory to ensure the quality of large shipments.

Tensile Testing Machine

General Applications For Mil-W-4088 Webbing

MIL-W-4088 Nylon Webbing is commonly used for parachute harnesses, tactical belt, carrying handles and drag handles.

Customized webbing service

JUDE is a manufacturer of functional webbing solutions for many market sectors. With a variety of manufacturing processes and capabilities, post-treatment of webbing, including:waterproof, flame retardant, IRR etc.

We also dye, cut, print, finish, coat, sew and assemble to deliver a webbing product specific to your requirements.Learn more

Our Factory

With a daily production capacity of up to 100,000 meters, we supply millions of meters of webbing each year to parachute equipment manufacturers around the world, including the USA, UK, France, Singapore, Thailand, etc.

200+ Weaving Machine

10+ Dyeing Machine

10+ Printing Machine

Factory production qualification